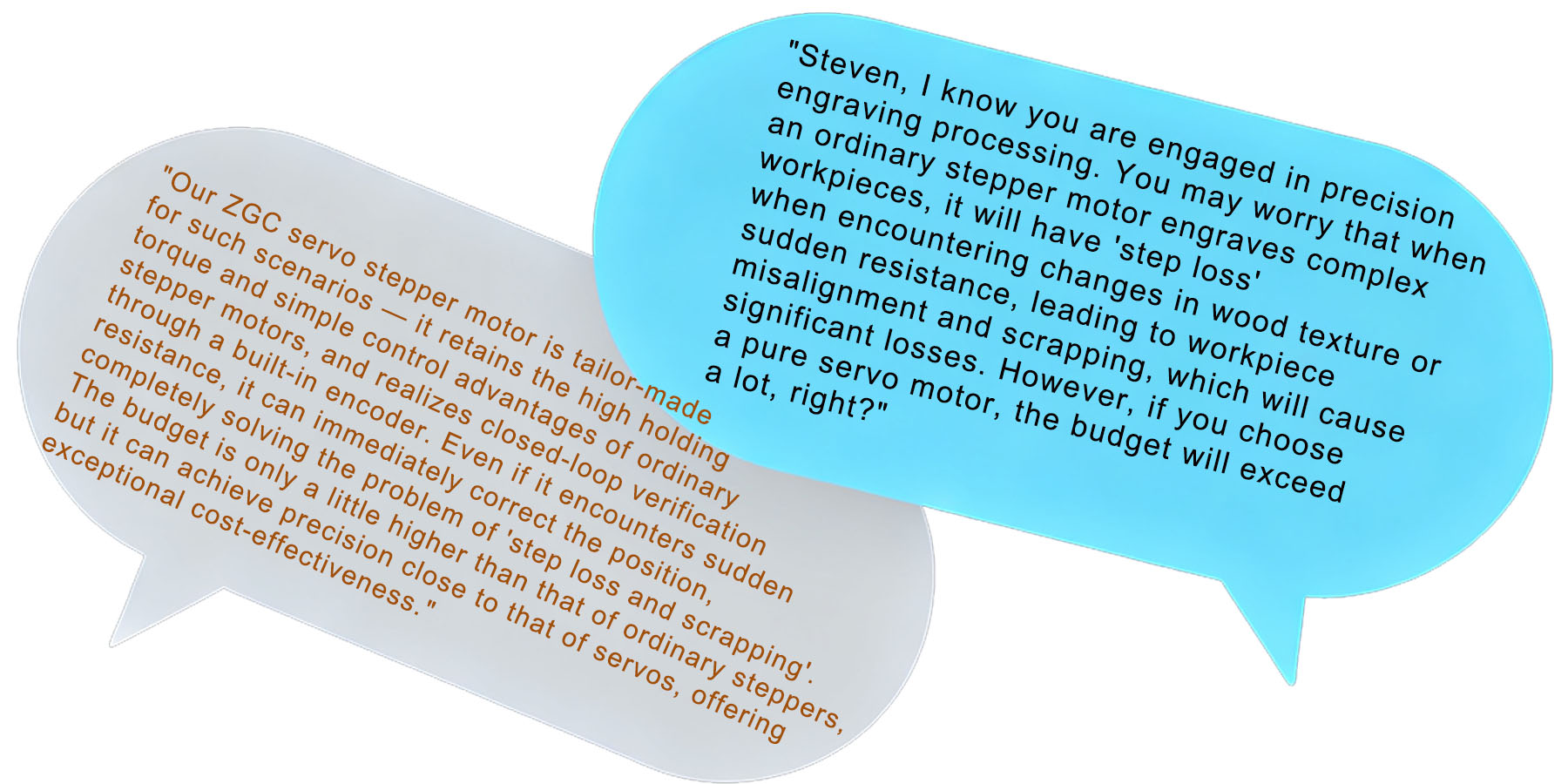

Are you concerned that a standard stepper motor might lose steps due to sudden resistance changes during complex carving, leading to misalignment and scrapped work? At the same time, is a true servo motor stretching your budget?

Hello~ Today, we’re going to talk about a core component that is frequently asked about during selection — servo stepper motor. Many people wonder when they hear this term for the first time: is it a servo or a stepper motor? Essentially, it is a high-performance stepper motor equipped with an encoder. Through closed-loop control technology, it strives to balance the convenience of stepper motors and the high precision of servo motors.

This is the product often called a ‘Step-Servo Motor’ in the market. But what is its proper technical name? It is a high-performance Closed-Loop Stepper. It combines the cost-effectiveness of a stepper with the reliability of servo-grade feedback.

Simply talking about the definition may be a bit abstract. Let’s first understand its core logic through a vivid daily analogy, then clarify its applicable scenarios through data comparison~

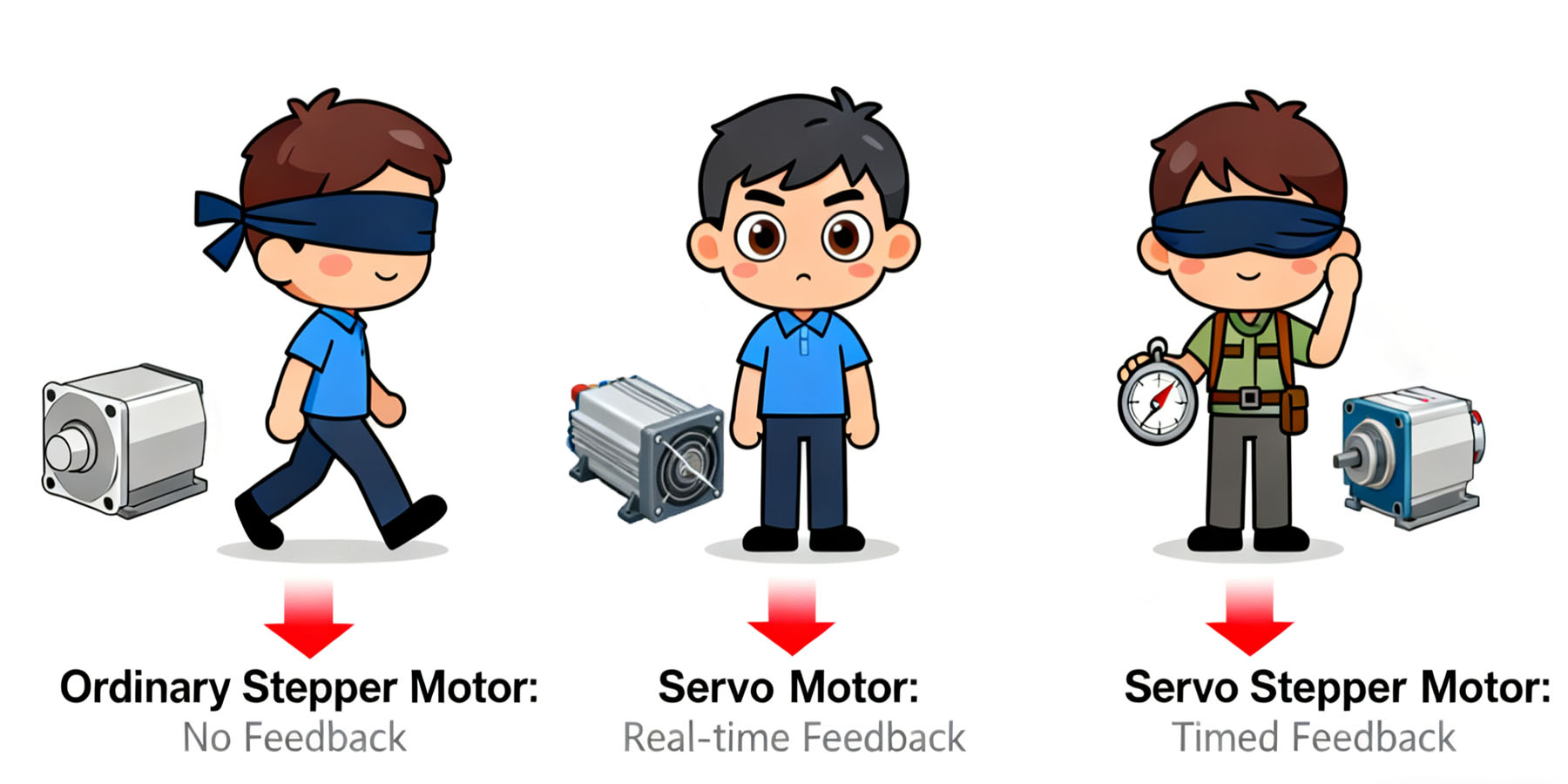

Three Vivid Analogies: Understand the Core Differences of Three Motors in Seconds

Let’s compare “the motor driving the load to reach a specified position” to “a person walking to the other end of the room”. The differences in the working logic of the three motors will become clear instantly:

- Ordinary stepper motor: Like a person walking with eyes blindfolded. It judges the position entirely by “counting steps” (receiving pulse signals). As long as the load is stable and there is no unexpected resistance, it can reach the position accurately. However, once it encounters sudden load (such as being pushed), it will have “step loss” (equivalent to falling). Moreover, because there is no feedback mechanism, it has no idea that an error has occurred, and subsequent work will be affected.

- Servo motor: Like a person keeping an eye on the target throughout the process. It monitors its position in real-time through an encoder (equivalent to eyes) and dynamically adjusts its pace and speed according to the target position every step. Even if it encounters unexpected interference, it can immediately correct the route, achieving full stability.

- Servo stepper motor: Like a person who “counts steps with eyes blindfolded + conducts regular checks”. It takes the “pulse counting” of the stepper motor as its core working mode, but it will conduct regular checks on the actual position through the encoder (equivalent to opening eyes to check every certain distance). Once a “step loss” error is found, it will immediately calibrate. It not only retains the simplicity of the stepper motor but also makes up for the shortcoming of anti-interference.

Core Technical Comparison Table: Key Parameters of Three Motors at a Glance

Are analogies not intuitive enough? This core parameter comparison table of Servo Stepper Motor vs. Ordinary Stepper Motor vs. Servo Motor helps you accurately match scenario requirements:

| Feature Dimension | Ordinary Stepper Motor | Servo Stepper Motor (Closed-Loop Stepper) | Servo Motor |

| Core Control Method | Open-loop control (no feedback) | Closed-loop control (encoder feedback) | Closed-loop control (real-time dynamic feedback) |

| Working Principle | Converts received pulses into fixed angles, assuming error-free execution by default | Mainly driven by pulses, with real-time verification and error correction via encoder | Continuously feeds back position/speed and makes dynamic adjustments after receiving commands |

| Precision Performance | High precision at rest, unable to recover after step loss | Extremely high, capable of preventing + correcting step loss, with precise terminal position | Extremely high, with stable precision during dynamic operation |

| Torque Characteristics | Torque drops significantly at high speeds

|

Retains stepper characteristics, with smoother torque curve after step-loss prevention optimization | Stable torque at high and low speeds, strong overload capacity |

| Cost Level | Lowest, basic model with cost-effectiveness | Medium (higher than ordinary stepper, lower than servo) | Highest, high performance corresponds to high cost |

| Core Advantages and Disadvantages | Advantages: Low cost, simple control, large static holding torque; Disadvantages: Prone to step loss, torque drop at high speeds, obvious vibration and noise | Advantages: Step-loss prevention, precise positioning, balanced cost-effectiveness; Disadvantages: Slightly inferior high-speed performance compared to servo, higher cost than ordinary stepper | Advantages: Top performance, high speed and high torque, fast dynamic response; Disadvantages: Complex control, high cost, requiring professional debugging |

| Applicable Scenarios | Cost-sensitive scenarios with stable loads such as laser engraving, 3D printers, and low-end CNC | Scenarios requiring precision + step-loss prevention with limited budget such as CNC engraving machines, precision dispensing machines, and automatic sorting equipment | Scenarios with high requirements for speed/torque such as industrial robots, high-speed packaging machines, and satellite communication antennas |

Final Summary: Core Value of Servo Stepper Motors

Simply put, a servo stepper motor is not a simple combination of “servo” and “stepper”, but a targeted solution for scenarios requiring “high precision + limited budget”. If the customer’s needs are “requiring both step-loss prevention and precise positioning, and not wanting to bear the high cost and debugging difficulty of pure servos”, then it is undoubtedly the best solution~

If you still have questions such as “which control systems are compatible with servo stepper motors” and “how to select different power models”, feel free to leave a comment in the comment section, and let’s discuss together!

一个回复

Let’s leave a message and discuss together