Servo Drive Selection Guide: Solving Servo System Interference Issues from Diagnosis to Product Selection

Servo Motor jitter, positioning inaccuracy? Your servo system may be experiencing interference. ZGC offers a complete solution—from on-site troubleshooting to servo drive selection and commissioning.

Servo Motor jitter, positioning inaccuracy? Your servo system may be experiencing interference. ZGC offers a complete solution—from on-site troubleshooting to servo drive selection and commissioning.

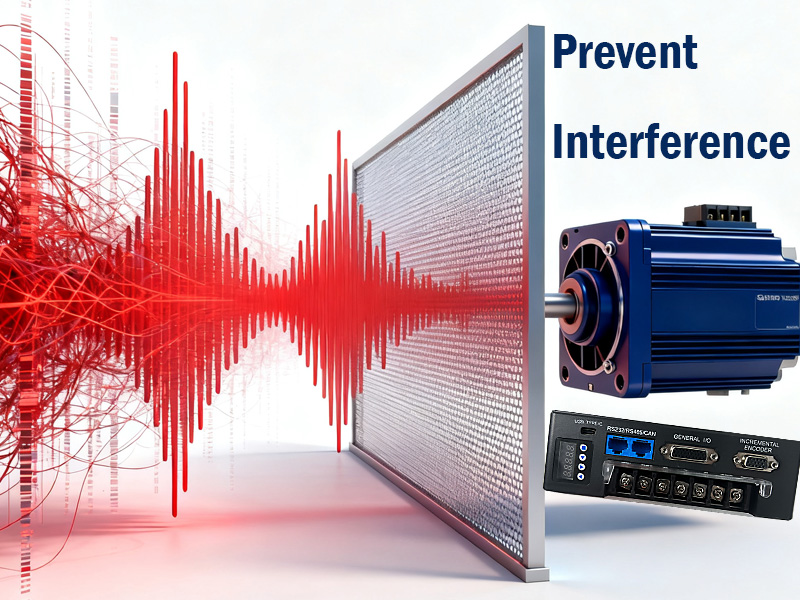

In complex working environments, servo motors are often susceptible to interference. Issues such as motor jitter and inaccurate positioning may be caused by interference. After ruling out hardware and installation failures, it’s essential to consider interference. Once mechanical installation and hardware issues are eliminated, electromagnetic interference (EMI) is often the hidden culprit. Follow these three troubleshooting steps to quickly identify and resolve the majority of interference problems:

Step 1: Check Grounding — Eliminate the Most Common Issue

Symptom Check: Verify whether the servo drive ground wire is connected.

Solution:

If not grounded: Immediately connect a standard ground wire to the drive. Proper grounding is fundamental to dissipating interference and ensuring system stability.

If already grounded: Try temporarily disconnecting the ground wire for observation. In some cases, improperly installed ground wires (e.g., mixed with neutral lines) can themselves become sources of interference.

Step 2: Install Ni-Zn Ferrite Core — Low Cost, High Effectiveness

Symptom Check: Abnormal encoder feedback signals or high-frequency interference during motor operation.

Solution: Attach nickel-zinc ferrite cores to both ends of the encoder cable and motor power cables. Ferrite cores effectively suppress high-frequency noise and are one of the most cost-effective solutions for interference issues.

Step 3: Optimize Wiring — Eliminate interference at the source

Symptom Check: The above methods are ineffective, or interference issues occur intermittently.

Solution: Strictly separate power lines (U/V/W) from control/encoder cables, maintaining a distance of at least 20 cm between them and avoiding parallel routing.

Use cables with shielding layers and ensure the shielding is grounded with a 360-degree connection.

Avoid Interference at the Source: Choose Servo Drives with Built-In Anti-Interference Design

High-quality servo drives incorporate advanced anti-interference technologies from the design stage. ZGC’s servo drive series products feature excellent electromagnetic compatibility (EMC) design and rigorous internal filtering circuits, effectively resisting external interference at the source and ensuring stable operation even in harsh grid environments.

ZGC Servo Drive Selection Guide: Model Comparison Table (Anti-Interference)

| Product Series | Rated Power | Input Voltage | Output Speed | Specific product functions can be searched on the product details page |

| NSP-SERVO-DC-01 | 100W | DC18-60V | 1-3500 RPM | |

| NSP-SERVO-DC-02 | 200W | DC18-60V | 1-3500 RPM | |

| NSP-SERVO-DC-05 | 500W | DC18-60V | 1-3500 RPM | |

| NSP-SERVO-DC-10 | 1000W | DC18-60V | 1-3500 RPM | |

| NSP-SERVO-DC-20 | 2000W | DC18-60V | 1-3500 RPM | |

| NSP-SERVO-AC-10 | 1000W | AC90-265V | 1-3500 RPM |

Unsure how to select the right model?

Our technical engineers can recommend the most cost-effective and stable servo drive model based on your specific servo motor parameters and operating environment.