In heavy industrial automation, choosing the wrong motor isn’t just about “insufficient performance”—it can lead to frequent downtime, gearbox damage, controller burnout, or even complete production line failure. Selecting a 2000W servo motor should never be limited to just the “power” rating. The real challenge is: how to maintain stable, efficient, and reliable operation under extreme loads, high dynamic response requirements, and harsh environments?

Introduction: Why “Power” Alone Doesn’t Define a Heavy-Duty Servo Motor

This article uses the ZGC130SV200 Series 2000W Servo Motor as an example to help you deeply understand the selection logic for heavy-duty servo motors and master the key technical details beyond the datasheet.

1. Core Parameter Calculations: Looking Beyond Power to Torque and Inertia

1.1 Torque: Not Just a Number, But a Guarantee of Continuous Output

Rated Torque: Must cover the load requirements during continuous operation.

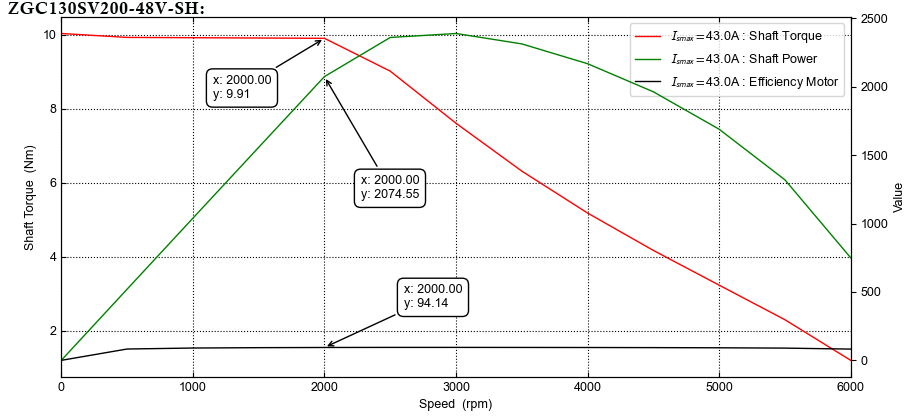

Taking the ZGC130SV200 as an example, its rated torque is 9.55 N·m, meaning it can continuously output this torque at 2000 RPM, making it suitable for continuous load scenarios like heavy material handling and CNC turntables.

Peak Torque: Used to handle startup, acceleration, or instantaneous overload.

This motor has excellent overload capacity, capable of outputting higher torque (typically 2~3 times the rated value) for short periods, suitable for dynamic processes like stamping and high-speed start-stop cycles.

Torque Calculation Formula:

T=F×rηT=ηF×r

Where TT is torque (N·m), FF is load force (N), rr is force arm radius (m), and ηη is system mechanical efficiency.

1.2 Speed: The Art of Balancing Speed and Torque

Rated Speed (2000 RPM): The standard speed at which the motor can operate continuously.

Maximum Speed (2500 RPM): The upper limit for short-term operation, typically used for rapid traverse or idle movement.

Using a gearbox can further amplify torque but reduces output speed—requires balancing based on actual process needs.

2. Inertia Matching: The Key to Stable Operation in Heavy-Duty Equipment

Inertia matching is a core metric for measuring system dynamic response and stability, and a key differentiator between “professional motors” and “ordinary motors.”

What is Inertia Matching?

Load Inertia JL : The rotational inertia of the driven components.

Motor Rotor Inertia JM : The motor’s own rotational inertia; ZGC130SV200 is as high as 1.2×10⁻³ kg·m², representing a high-inertia design.

Recommended Inertia Ratio:

High-precision scenarios (e.g., CNC machine tools): JL/JM<5:1

General automation (e.g., handling robots): JL/JM < 10:1

Advantage of ZGC130SV200:

Its high rotor inertia effectively absorbs load fluctuations, suppressing vibration and oscillation, making it particularly suitable for heavy robotic arms, large-inertia turntables, and other high-dynamic load scenarios.

Technical Specifications Table

|

Feature |

Specification |

|

Model |

ZGC130SV200 |

|

Rated Power |

2000W (2.0 kW) |

|

Frame Size |

130mm |

|

Rated Torque |

9.55 N.m |

|

Rated Speed |

2000 RPM |

|

Rated Voltage |

48-72VDC |

|

Encoder Type |

17-bit / 23-bit Absolute Encoder (Optional) |

|

Protection Class |

IP65 (Waterproof and Dustproof) |

|

Insulation Class |

Class H/F |

3. Environmental Suitability & Physical Specifications: Built for Harsh Industrial Environments

3.1 Protection Class: IP65, Dust and Water Resistant

Industrial environments often involve dust, oil, and water splashes. The IP65 protection class ensures reliable motor operation under harsh conditions (excluding the output end).

3.2 Thermal Design: Efficient Thermal Management is Key

- Winding resistance as low as 0.03Ω (48V model), reducing copper loss at the source.

- H-class temperature-resistant cables + F-class insulation system, combined with an optimized heat dissipation structure, ensures controlled temperature rise under S1 duty cycle, suitable for long-term heavy-load operation.

3.3 Frame Size: 130mm, the “Golden Standard” for Heavy-Duty Drives

The 130mm frame strikes a balance between structural rigidity, heat dissipation area, and mounting compatibility in the 2kW power range, making it an ideal choice for heavy-duty applications.

4. Control Feedback System: Encoders Determine Precision and Reliability

Absolute Encoder: No Position Loss After Power Loss

The ZGC130SV200 comes standard with an absolute encoder, eliminating the need for homing after each power cycle. This improves equipment startup efficiency and positioning reliability, especially suitable for heavy CNC, multi-axis synchronization, and other high-end applications.

Protocol Compatibility:

Supports mainstream industrial protocols such as EtherCAT, CANopen, Pulse/Direction, facilitating integration into existing control systems.

5. Typical Case Study: Application of ZGC130SV200 in Heavy-Duty CNC Cutting Machines

Challenges:

- High load inertia causing positioning jitter during frequent start-stop cycles.

- High temperature rise during continuous processing affecting precision and lifespan.

Solution:

- Adopted ZGC130SV200-48V-SH with absolute encoder and matching drive.

Results:

- Positioning accuracy improved by 30%, with smooth, oscillation-free operation.

- Temperature rise reduced by 15%, supporting long-term continuous processing.

- System reliability significantly enhanced, extending maintenance intervals.

6. Selection Checklist: Is Your Application Suitable for a 2000W Servo Motor?

Before finalizing your decision, confirm the following:

✅ Is continuous operating torque ≤ 9.55 N·m?

✅ Is load inertia ratio within 10:1?

✅ Does power supply voltage match (48V / 60V / 72V DC)?

✅ Are dust/water protection requirements needed (IP65)?

✅ Are absolute encoder and brake options required?

How to Integrate ZGC130SV200 into Your System?

ZGCmotor not only provides motors but also offers matching servo drives, gearboxes, brakes, and other integrated solutions. We support customized design and can respond quickly based on your mechanical interface, communication protocol, and performance requirements, helping you achieve system integration at a better cost.

Next Steps:

If you’re selecting motors for heavy loads or looking to optimize your existing drive system, feel free to download our detailed datasheet or contact technical support for a customized solution.

📥 Download ZGC130SV200 Complete Datasheet Now

https://zgcmotors.com/servo-motor/90mm-servo-motor/zgc130sv200-series-2000w-servo-motors/

🛠 Contact Engineers for Free Selection Support

One Response

How are you?