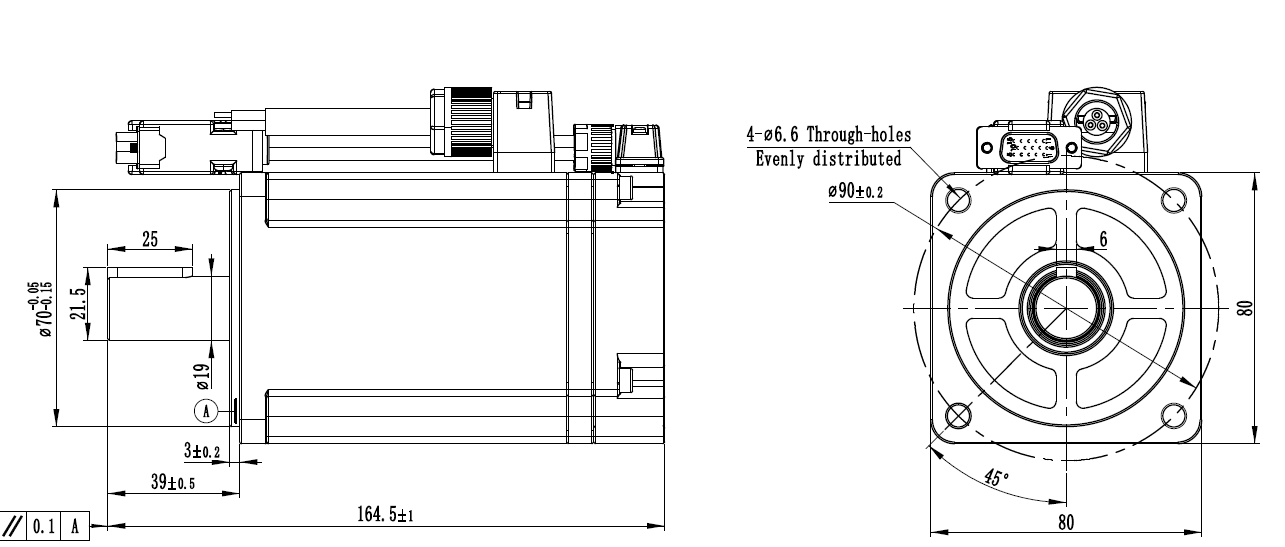

- 80mm Medium-High Inertia Servo Motor, 750W, 48VDC/60VDC/72VDC

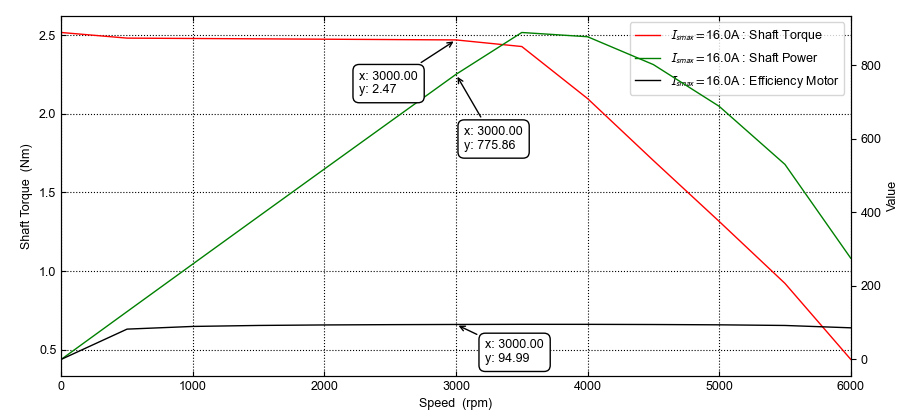

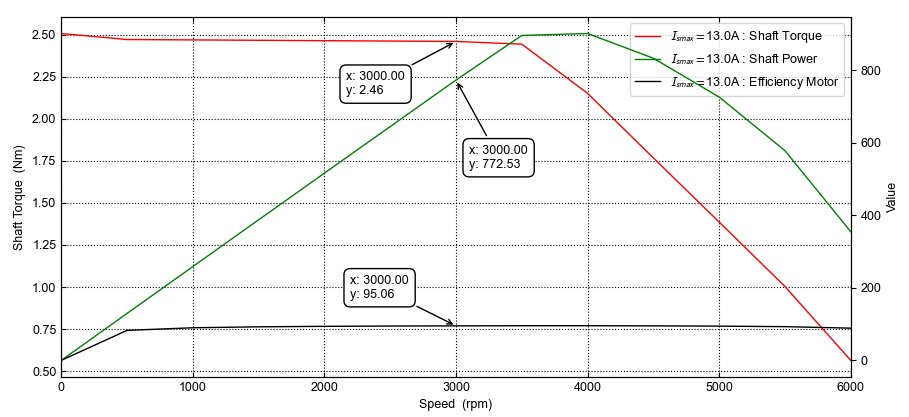

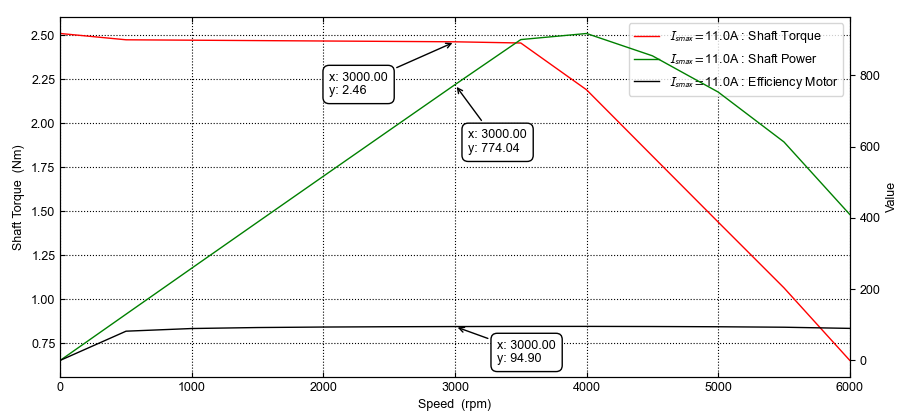

- Rated Torque: 2.39 N.m

- Rated Speed: 3000 RPM

- Maximum Speed: 4500 RPM

- Operating Environment: -20℃ to 60℃, Humidity < 90%

- Encoder Type: Absolute Encoder

- Options: Gearbox, Brake

- Certifications: CE, RoHS