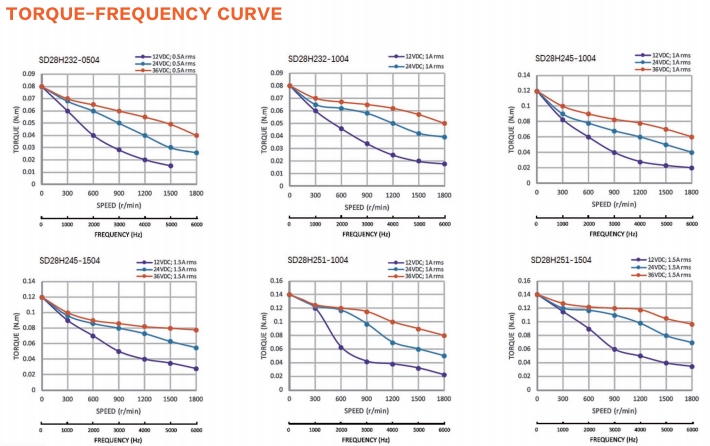

- Precise Micro-Torque: Delivers 0.1-0.2 Nm of controlled force for delicate and lightweight motion control.

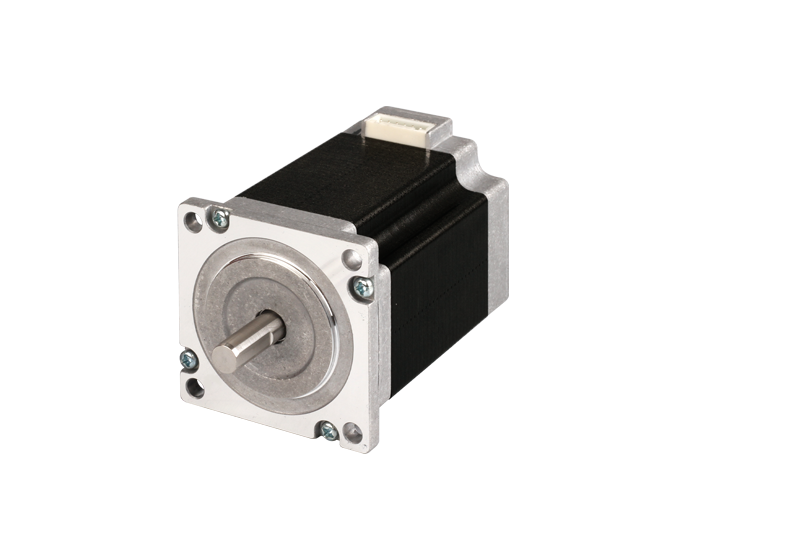

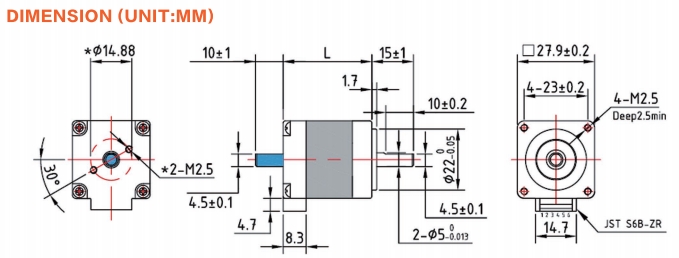

- Compact & Efficient Design: Built to the NEMA 11 standard (28mm), optimized for space-constrained applications.

- Accurate Stepping: 1.8° step angle ensures smooth operation and precise repeatable positioning.

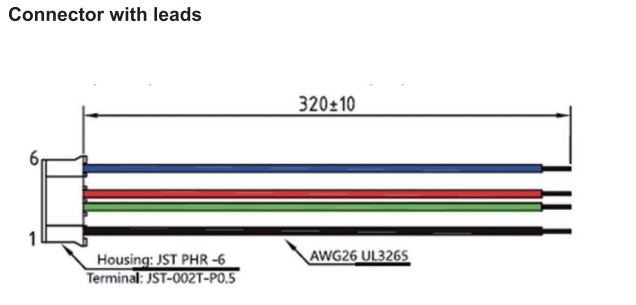

- Reliable Connectivity Wiring: The leads allow for direct termination to your driver or control system, enabling a customized and secure installation.

- Versatile Application: Monitoring equipment, textile equipment, printing machine