| 1. Basic Parameters |

Input Power: |

Three-phase AC 220V |

| Control Methods: |

Position Control, Speed Control, Torque Control |

| 2. Operating Environment |

Operating Temp/Humidity: |

0~40℃; 40%~80% RH (no condensation) |

| Storage Temp/Humidity: |

-40~50℃; ≤80% RH (no condensation) |

| Vibration: |

≤0.5G |

| Atmospheric Pressure: |

86-106kPa |

| Installation Site: |

Well-ventilated, low moisture/dust; free of corrosive/flammable gases, oil fumes; no moisture or direct sunlight |

| 3. Core Features |

Speed Frequency Response: |

≥200Hz |

| Speed Fluctuation: |

<±0.03% (load 0~100%); <±0.02% (power supply -15%~+10%) |

| Speed Regulation Ratio: |

1:3000 |

| Pulse Frequency: |

≤500kHz |

| Control Input: |

Servo Enable, Alarm Reset, CCW Drive Inhibit, CW Drive Inhibit, Homing Control |

| Control Output: |

Servo Ready Output, Servo Alarm Output, Position Completion Output, Mechanical Brake Output |

| Position Control: |

Input Modes (Pulse+Sign/CW Pulse+CCW Pulse/2-Phase A/B Quadrature Pulse/Communication Command); Electronic Gear (1-1000/1-1000) |

| Speed Control: |

Analog Speed Control, Communication Speed Control |

| Acceleration/Deceleration: |

Configurable (1-1000ms/1000min) |

| Monitoring Functions: |

Rotational Speed, Motor Torque, Motor Current, Command Pulse Frequency, Voltage, Alarms, etc. |

| 4. Installation Requirements |

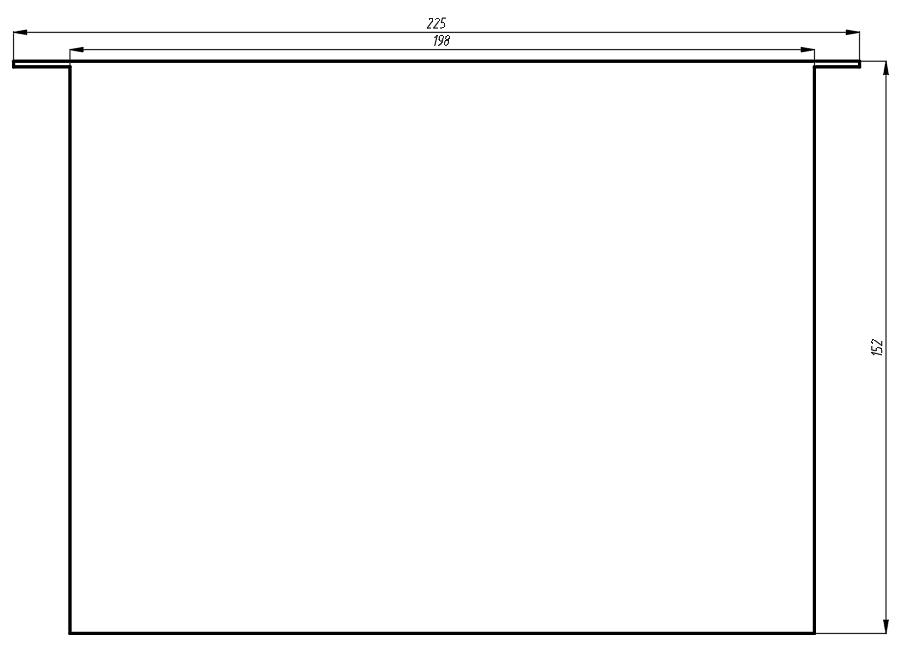

Installation Orientation: |

Preferred vertical upright |

| Horizontal Installation: |

Route cable outlets downward (to prevent liquid from entering the motor) |

| Vertical Installation (with gearbox): |

Prevent gearbox oil from seeping into the motor shaft |

| Motor Shaft: |

Ensure sufficient extension (to avoid vibration during operation) |

| Note: Do not strike the motor with a hammer during installation/removal (to prevent shaft/encoder damage) |

| 5. Wiring Specifications |

Wire Gauge: |

R, S, T, U, V, W, PE terminals ≥ 1.5mm² (AWG14-16); r, t terminals≥0.75mm² (AWG18) |

| Terminals: Use pre-insulated crimp terminals; ensure secure connections |

| 6. Protection Functions |

Overvoltage Protection, Undervoltage Protection, Short-Circuit Protection, Drive Overheating Protection, Overload Protection, Overcurrent Protection, Excessive Position Error, Encoder Fault, Alarm Output |