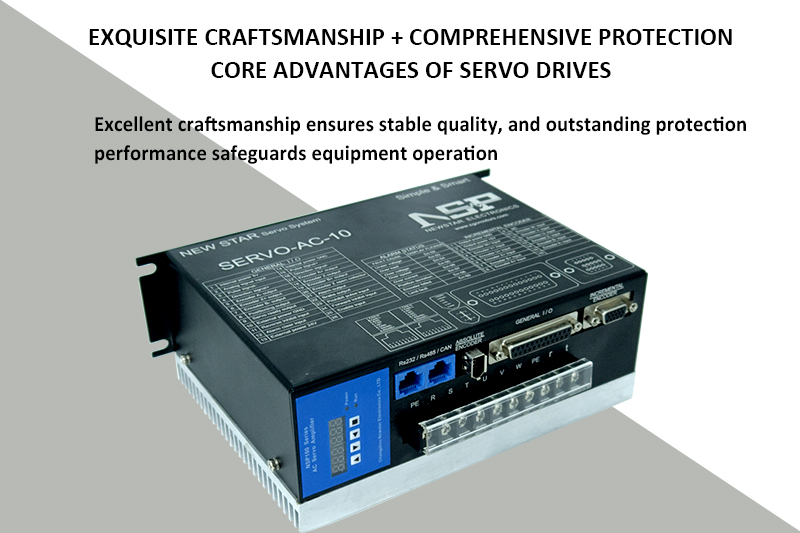

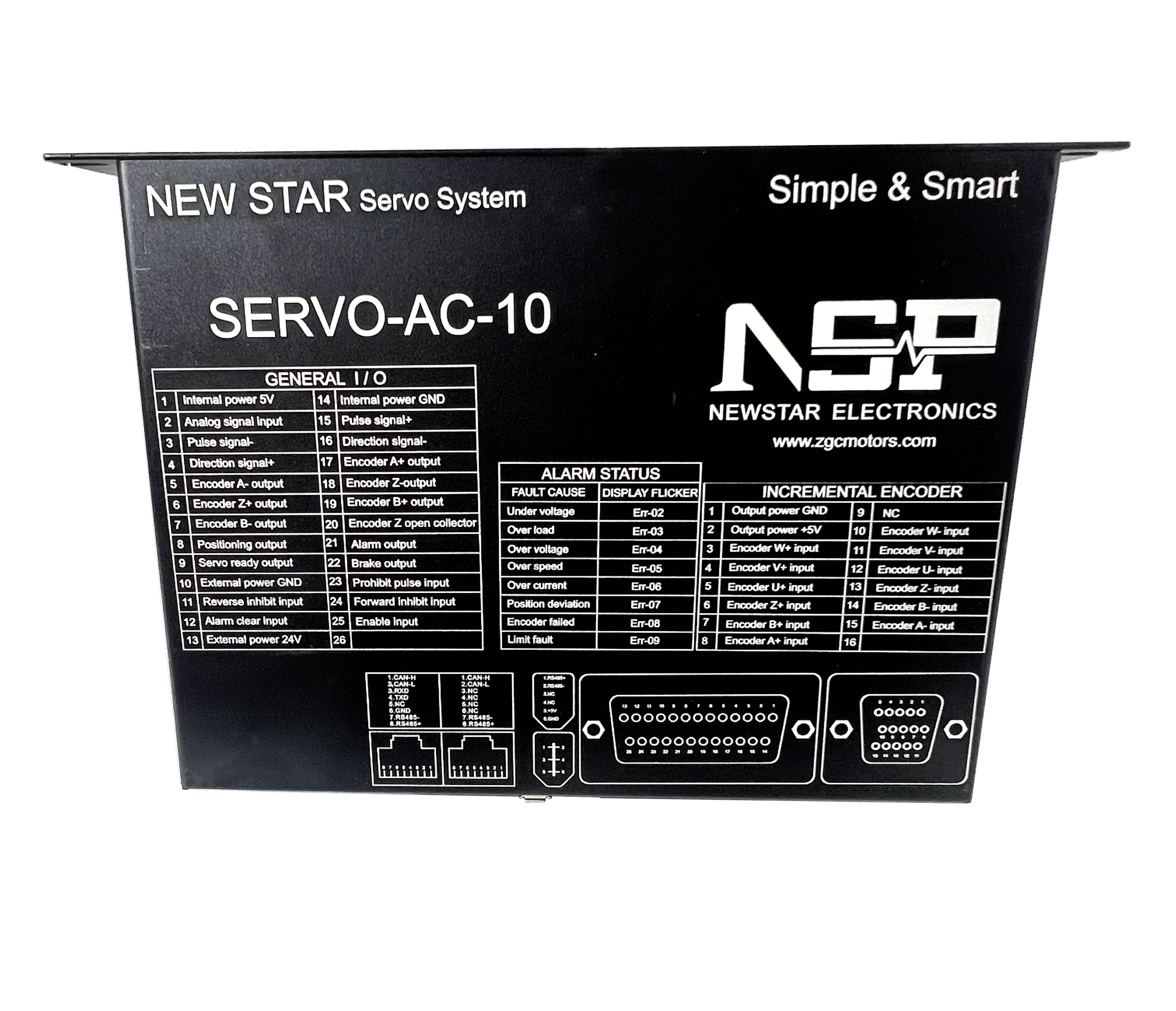

NSP-SERVO-AC-10 series is a high-performance AC input servo drive engineered for 500W-1000W high-voltage DC servo motors, encoder-equipped BLDC motors, and coreless motors. Featuring a wide 90V-260V AC input range, it delivers industry-leading precision (1 pulse repeat tracking error, 1 RPM speed control accuracy) and supports flexible control modes (position/speed/torque via external pulse, analog input, RS485, or CAN bus). With comprehensive protection functions (undervoltage, overvoltage, overload, etc.) and easy PC debugging via RS232, it is ideal for precision motion control, industrial automation, and robotics applications.

- Operating Voltage: 90V-260V AC

- Peak Output Current: 1A–10A

- Repeat Tracking Error: 1 pulse

- Speed Control Accuracy: 1 RPM

- Max Speed: 5000 RPM

- Control Modes: Position/Speed/Torque (RS485/CAN)

- Compatible Motors: 500W-1000W DC/BLDC/Coreless

- Protection: Undervoltage/Overvoltage/Overload/Encoder Error