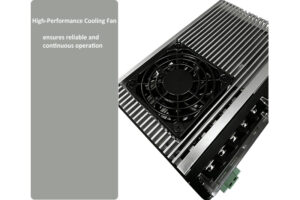

The NSP-SERVO-DC-10 series servo driver is a cost-effective servo motor driver independently developed by ZGC Company. Equipped with a high-performance processor and integrated with advanced control technology, it features high integration and comprehensive protection measures. It achieves lower noise, lower temperature rise, higher rotational speed, and boasts excellent stability.

- Operating Voltage: 24V-60V DC

- Output Current: Peak 1A-25A

- Rated Speed: 3000 RPM, supports up to 5000 RPM

- Compatible Motors: 500W-1000W low-voltage DC servo motors (24V-60V), Brushless DC Motors (BLDC) with encoder, or coreless motors.

- Fault Protection: Includes undervoltage, overvoltage, overload, overcurrent, alarm output, excessive position error, encoder error, etc.

- Control Modes: External pulse, analog input, RS485, CAN bus communication control, etc., supports position, speed, and torque control modes.