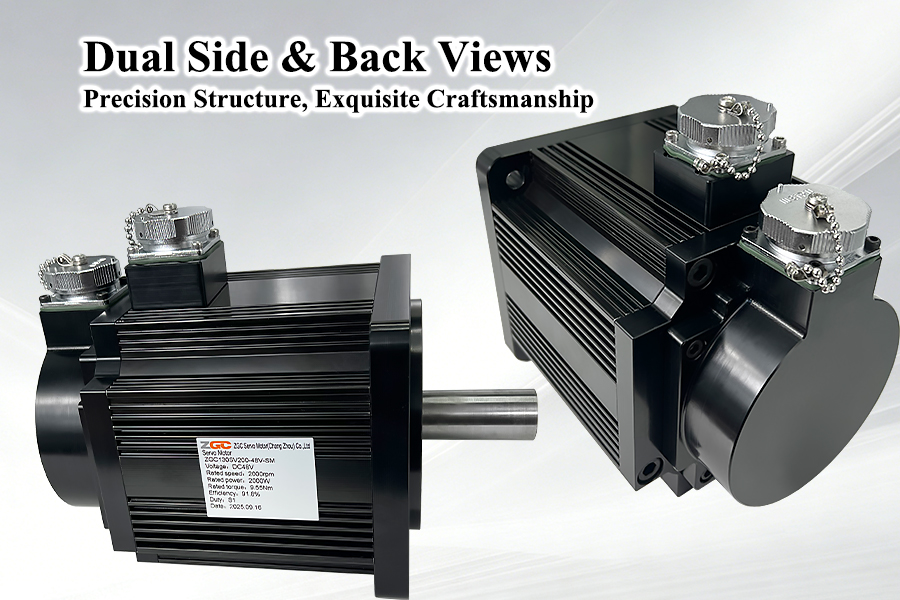

- 130mm High-Inertia Servo Motor, 2000W, 48VDC/60VDC/72VDC

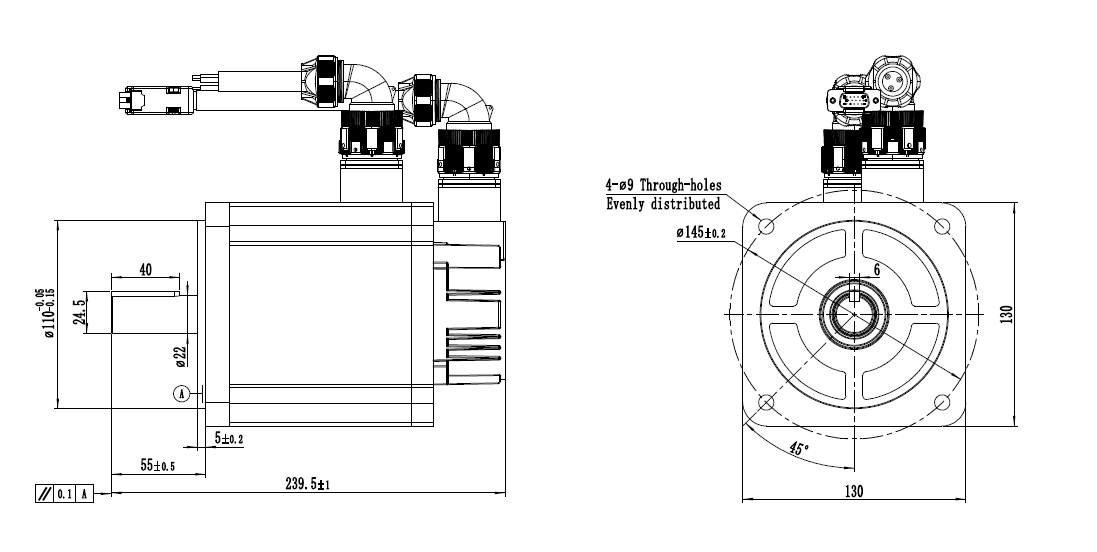

- Dimensions: 130 mm (W) × 130 mm (D) × 5mm (L, including shaft)

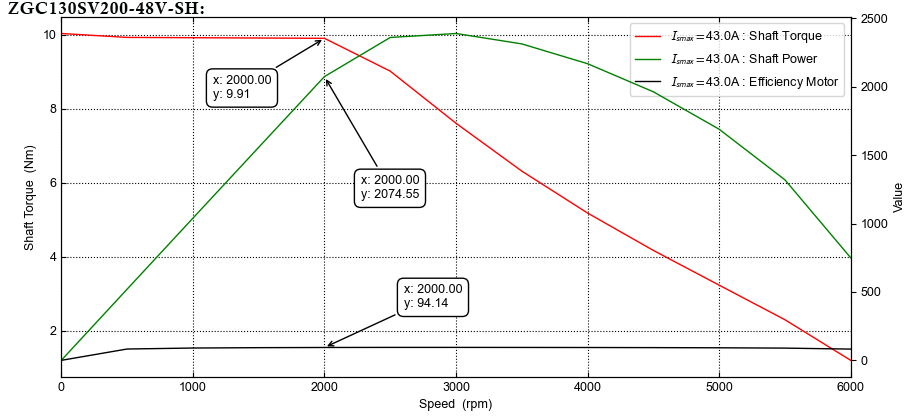

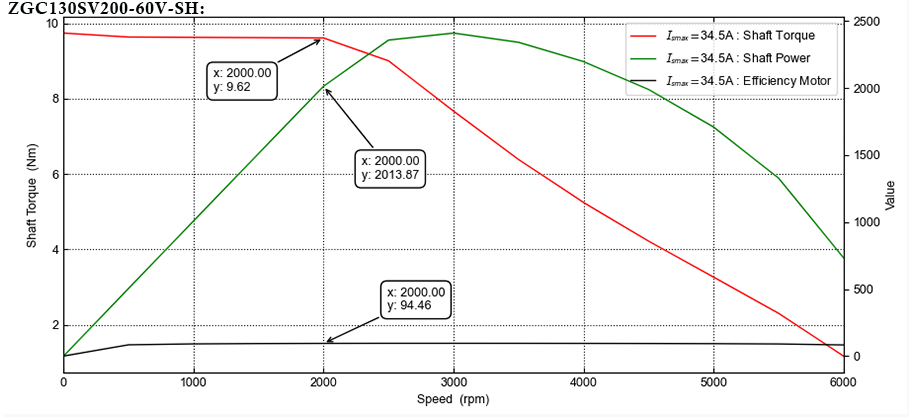

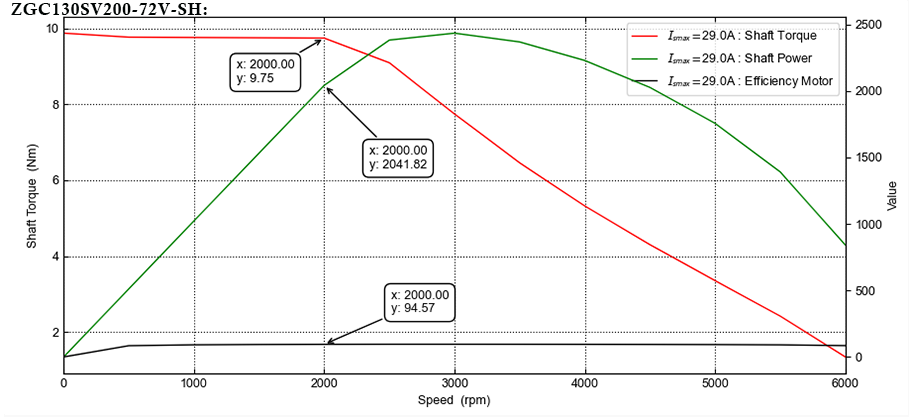

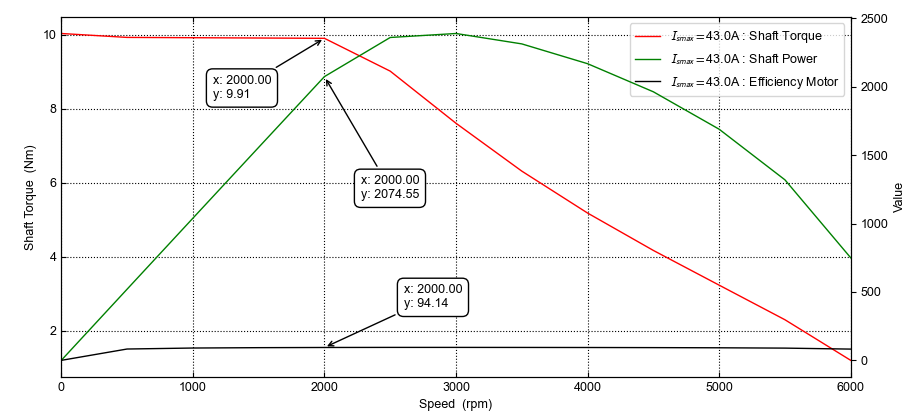

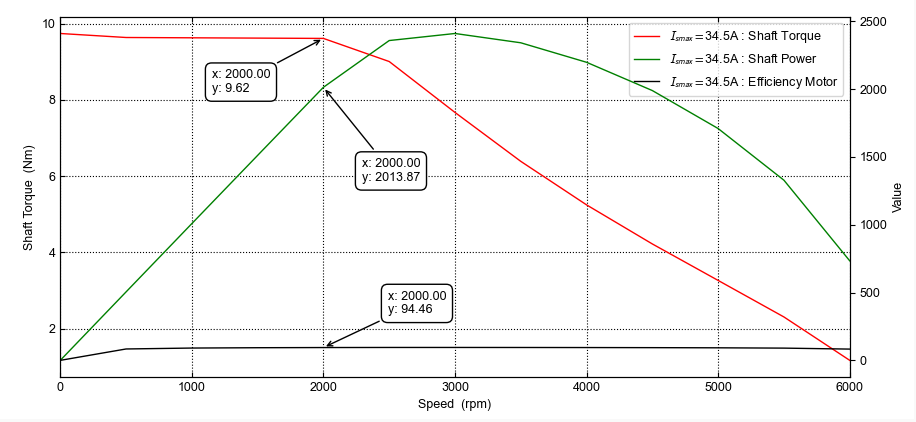

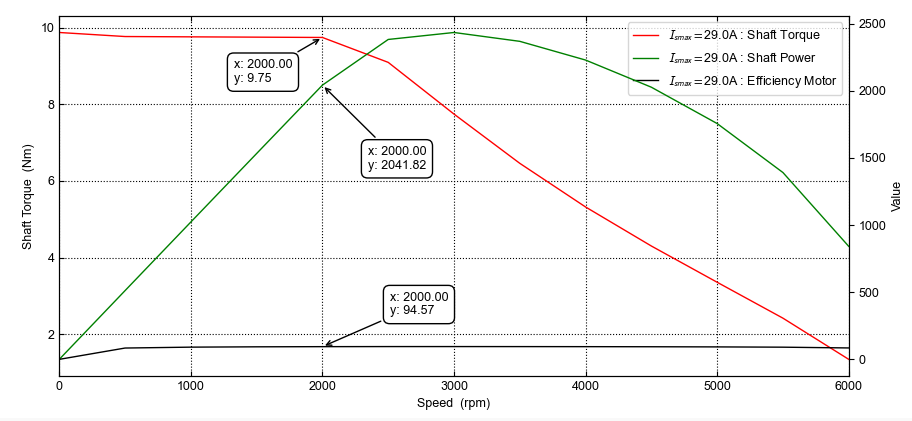

- Rated Power: 2000W

- Rated Torque: 9.55 N·m

- Rated Speed: 2000 RPM | Max Speed: 2500 RPM

- Electrical Characteristics: 10-pole design, High-Inertia, Class F insulation

- IP Rating: IP65 (excluding output end)

- Operating Environment: -20℃ ~ 60℃, Humidity < 90%

- Encoder Type: Absolute value encoder

- Options: Gearbox, Brake

- Certifications: CE, RoHS