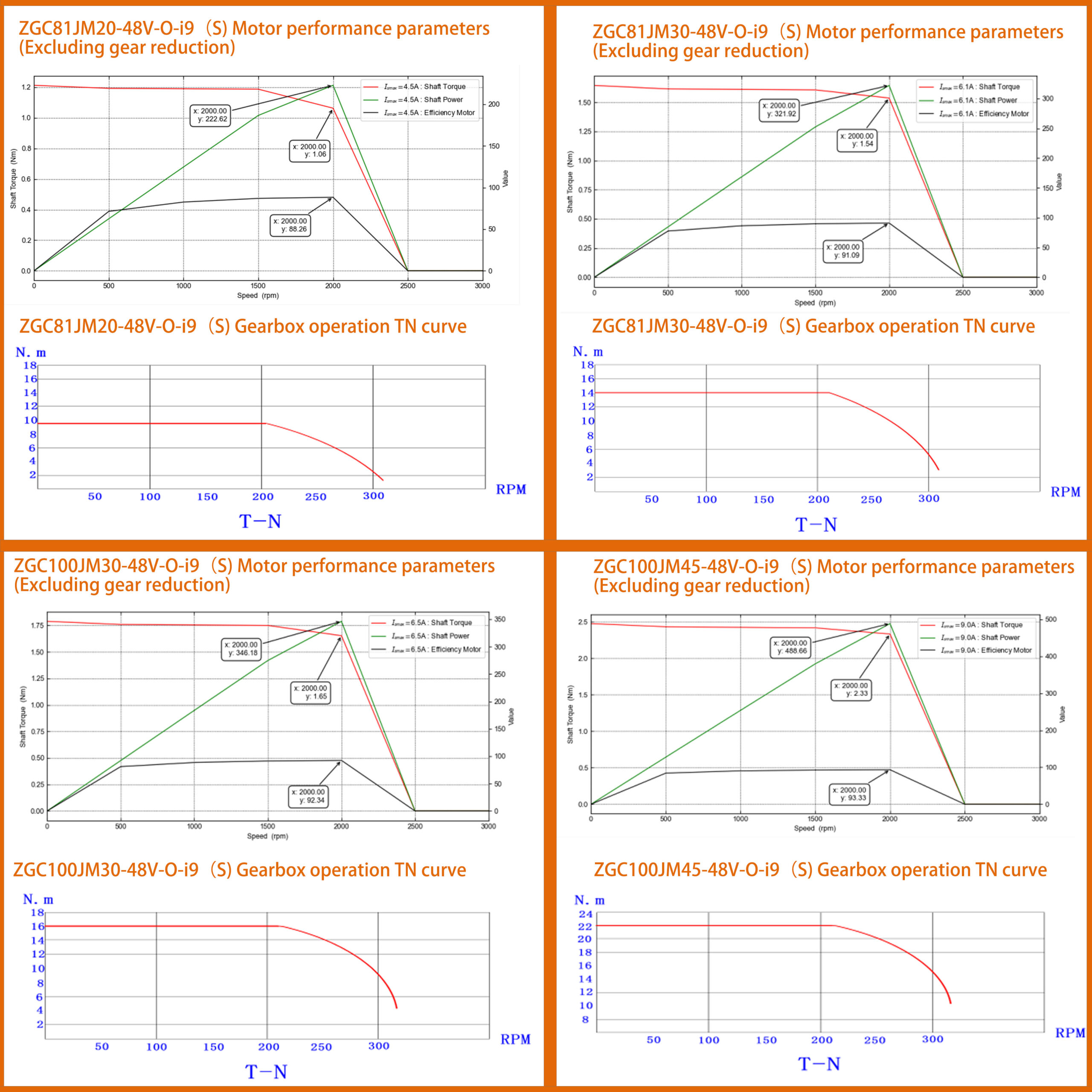

- Models: ZGC81JM20-48V-O-i9(S) / ZGC81JM30-48V-O-i9(S) / ZGC100JM30-48V-O-i9(S) / ZGC100JM45-48V-O-i9(S)

- Number of Poles: 40

- Phase: 3

- Voltage Range: 24-60V

- Rated Voltage: 48V

- Rated Torque: 9-22 N.m

- Peak Torque: 18-44 N.m

- Rated Power: 200W/300W/340W/450W

- Safety Class : IP(54) Excluding output and driver interfaces end

- Encoder Type: Absolute value

- Drive Method: FOC