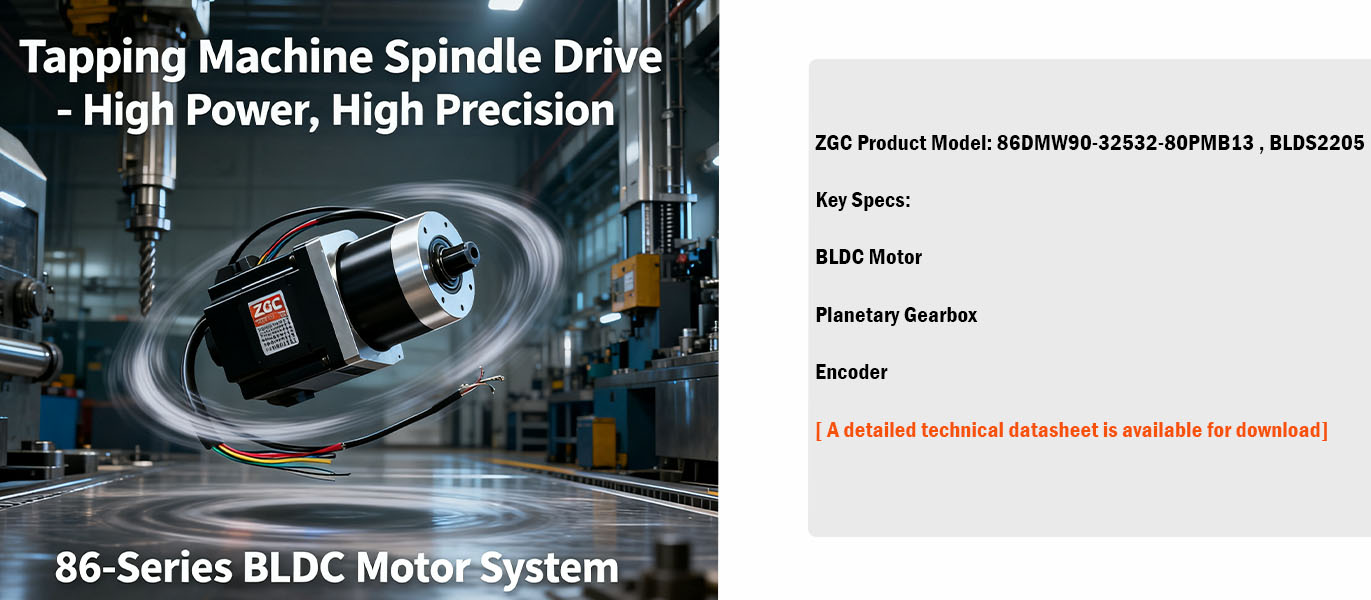

Tapping Machine Spindle Drive – High Power, High Precision

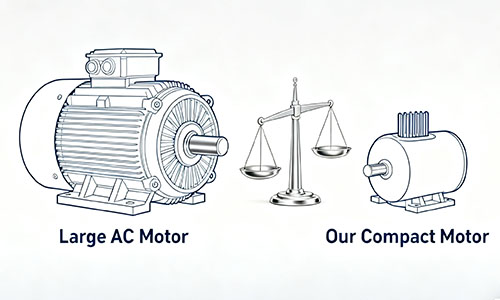

Traditional tapping equipment using AC motors is often bulky, slow to respond, and lacks the precision required for modern, high-cycle, accurate machining processes.

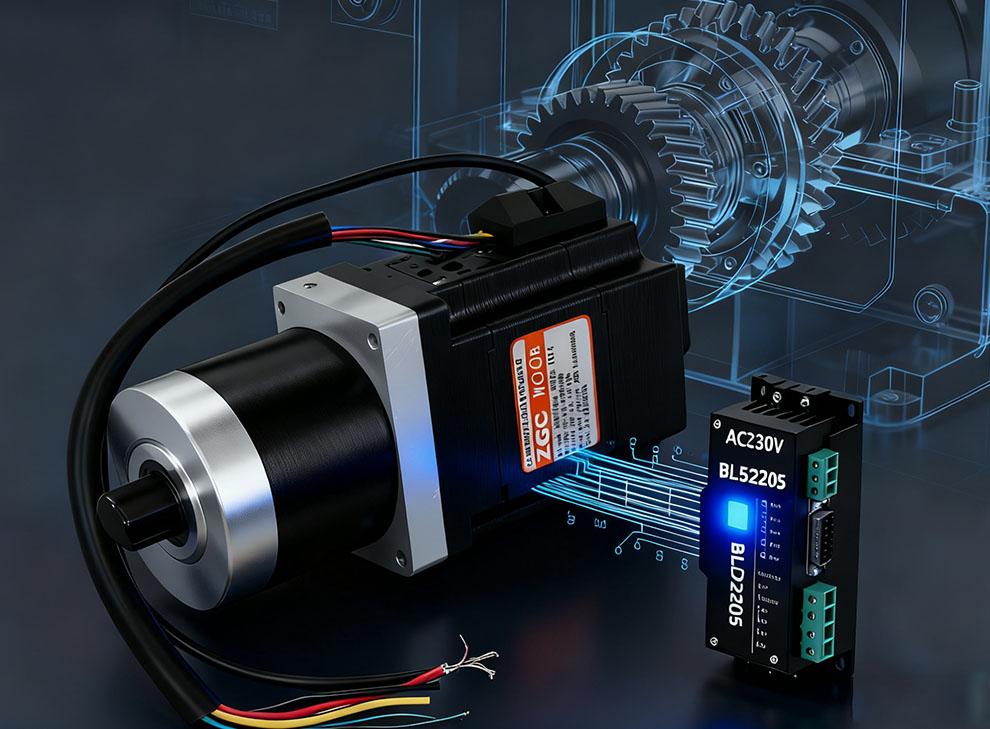

ZGC’s 86-series high-torque BLDC motors, combined with precision planetary gearboxes and encoders, provide a high-power, compact, and responsive spindle drive solution for tapping machines. The compatible AC230V driver (BLDS2205) offers a complete system ready for integration.

Provides greater power in a smaller size, effectively replacing larger AC motors.

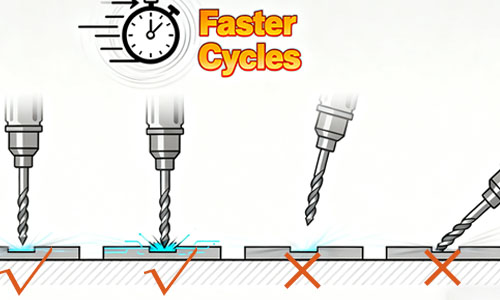

Enables fast start-stop cycles, significantly increasing tapping throughput.

Integrated encoder feedback ensures consistent tapping depth and quality.

Pre-configured motor and driver combinations simplify machine design and reduce time-to-market.

Changzhou ZGC Mechanical & Electrical Co., Ltd. is committed to being your trusted partner by delivering cost-effective standard and customized solutions. Headquartered in China’s Motor City, Changzhou.

©2025 ZGC. All Rights Reserved.